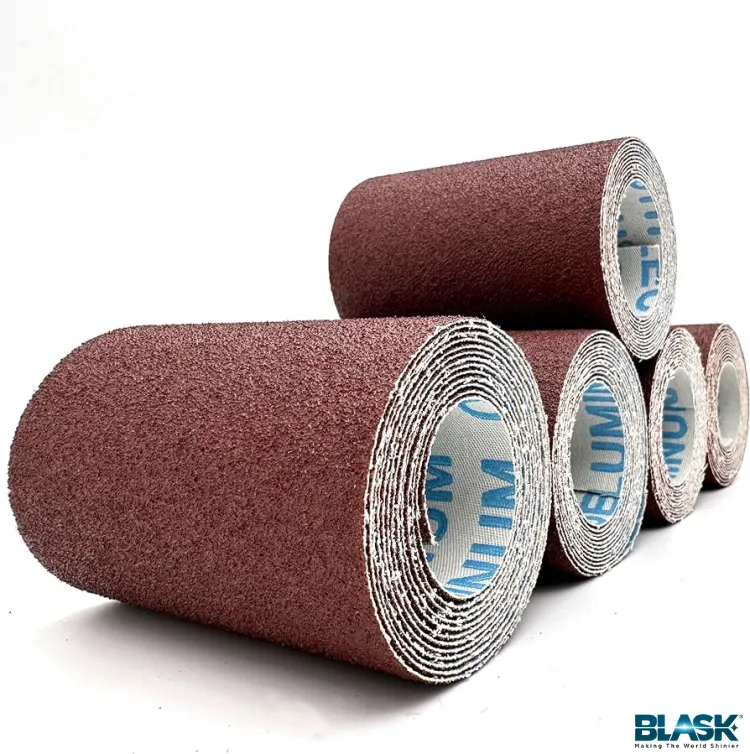

fine grit sandpaper is one Tools Essential and indispensable in many works, this type of sandpaper is distinguished With its molecules Microfiber that provides smoothness For surfaces Which makes it the best choice for obtaining a flawless final finish.

fine grit sandpaper is used in many applications to smooth surfaces before painting and remove small defects and in carpentry, metal and plastic works as well, because it works precisely, which leads to satisfactory results.

In this article, we will talk about the importance of sandpaper, its different types, and how to use it correctly to achieve the best results through Blask Company, the exclusive and sole agent for PODIM & Pegas & Paco. Follow along with us.

Types of sandpaper

Sandpaper comes in different types, each of which is designed to suit a type of work and different materials. Here are some common types divided into:

- Dry sandpaper: It is one of the most common sandpapers due to its frequent use in finishing works.

- Water sandpaper: It is a type that is used with water, and is used for wet finishing.

- Sponge sandpaper: It is a type that contains a sponge and is used for manual finishing work.

There are also types of sandpaper that differ according to the number of abrasive grains, as sandpaper varies based on the number of sand grains, which range from 40 to 6000 grains of sand, depending on the type of paper. Here are the grades of sandpaper grains and what they are used for:

- Sandpaper 40-60: It is used to remove old paint and rough wood.

- Sandpaper 80-120/ is used to remove scratches and smoothen surfaces.

- Sandpaper 150-180: It is used to smooth surfaces.

- Sandpaper 220-320: It is used to prepare surfaces and prepare them for final finishing works.

- fine grit sandpaper 400-6000: It is used to smooth surfaces.

Sanding increases the quality and ease of sanding wood, because the greater the sand grains, the faster the sanding.

Fine grit sandpaper uses

fine grit sandpaper has many uses in various fields that require precision and smoothness of finish RoofsHere are the most prominent uses of fine grit sandpaper:

- Finishing wooden surfaces

- Fine wood sandpaper is used to smooth wooden surfaces after the initial sanding in order to remove any scratches or small defects.

- Surface preparation

- It is used to prepare surfaces before painting, which ensures better adhesion of the paint to the furniture or wall.

- Soften edges

- fine grit sandpaper helps soften sharp edges and remove fine excess from the wood.

- Remove small defects

- fine grit sandpaper can be used to remove small defects such as scratches on wood and metal.

Its versatility and wide range of applications makes it an essential tool. Whether it is preparing surfaces, removing imperfections, or achieving final finishes, sandpaper continues to play a vital role in enhancing the quality and aesthetics of various products and projects.

It is also used to maintain some tools and equipment by removing small defects, making fine grit sandpaper a vital tool in many areas that require fine finishes.

Types of Fine grit sandpaper for metal

Iron sandpaper comes in several types, each designed to achieve the best performance with specific materials and different use cases. Here are some common types:

- Sandpaper carbide Silicon Carbide

- This type is common in metal sanding due to its high hardness and its ability to work with different metal surfaces. It is used to remove old paint or rust and can also be used in the final finishing of metals.

- Aluminum oxide sandpaper

- Aluminum oxide sandpaper is suitable for light metals such as aluminum and copper With his durability Its effectiveness in removing impurities from metal surfaces makes it a good choice for manual and industrial works.

- Zirconium Alumina sandpaper

- It is a type of sandpaper for metals. This type is used for sanding strong metals such as stainless steel. Zirconium is also characterized by its ability to endure and maintain its efficiency for a long time.

- Ceramic Sandpaper

- This type is considered one of the most efficient types for sanding hard metals and is characterized by its high performance and long life.

Each of these types has certain characteristics that make it suitable for certain tasks when working with metals, such as rust removal, paint preparation, and final finishing.

Learn more about : sandpaper for metal

How to use sandpaper

In order for sanding paper, as sandpaper is known in English, to be used effectively, you must first choose the appropriate type of sandpaper according to the surface to be treated and smoothed, once the appropriate sandpaper has been chosen.

It is held by hand and pressed while moving it in circular motions or in one direction on the surface. It is preferable at first to use sandpaper. harsh To remove large impurities, then use fine grit sandpaper to obtain a smooth final finish.

What are the uses of sandpaper?

Sandpaper has many diverse uses in various fields, such as:

- Softening wooden surfaces

- Sandpaper is used to prepare the wood To paint Polishing helps remove impurities and obtain a smooth surface.

- Remove old paint

- It helps in removing layers of old paint and varnish from various surfaces, allowing By renewing it And repainted.

- Metal cleaning and polishing

- It is used to clean and polish metal surfaces to remove rust, which helps restore their shine.

- Preparing the surface for painting

- Sandpaper is used to prepare various surfaces for painting, whether wood or metal To return Paint it again.

- Roof repair

- It helps repair small scratches and cracks, which contributes to improving the appearance of the surface before painting.

- Final finishing

- It is used to obtain a soft and smooth final finish on various surfaces.

You can obtain fine or coarse sandpaper to complete the sanding and finishing process by visiting the Blask Solutions website, the sole and exclusive agent for PODIM & Pegas & Paco, where you will find an excellent collection of high-quality sanding materials from international brands.

What is the number of fine grit sandpaper?

fine grit sandpaper is one of the tools used for surface finishing. The fine sandpaper usually ranges between 220 and 800.

The higher the number, the smaller the sanding grains, which provides smoother and finer surfaces. For example, sandpaper with a number of 220 is used for final finishing, while sandpaper with a number of 800 or more is used to obtain a smooth finish.

Because coarse and fine grit sandpaper grits are used differently, Blask has created grades consisting of different grades of sanding grit to help consumers decide which type is best for their work.

The coarse grade includes, which is classified as ultra-coarse With granules Sand 24, 30 and 36 grit while fine grit sandpaper includes paper With granules Sandy with numbers from 400 and 800.

Sanding brush

A sanding brush is a specialized tool used for sanding and cleaning and is a great choice for projects that require access to tight areas.

The sanding brush consists of bristles and fibers covered with sanding materials, which gives it the ability to remove impurities and smooth surfaces with high efficiency. The sanding brush can also be used on many diverse materials such as wood and metal, which makes it multi-use.

Thanks to its innovative design, the sanding brush provides better control in various sanding operations and helps in achieving precise results. It is also ideal for handicrafts, especially those that require removing impurities from surfaces and tight corners.

Mattress 60*30

The 60*30 cm sanding brush is a tool used in many applications that require quick coverage. This brush is distinguished by its large size, which provides high efficiency in sanding operations, as it allows dealing with larger areas in less time.

Thanks to its sturdy design, the brush has a high carrying capacity that allows it to work on various types of surfaces, whether wooden or metal, making it the ideal choice for large projects that require precise sanding.

Kitchen marble sander

Sanding kitchen marble is an important step in preserving its appearance and prolonging its life, as over time marble surfaces can become exposed. For God’s sake And stains that affect its attractiveness.

Through the sanding process, the damaged surface layer is carefully removed, revealing a new, smooth and shiny layer. This process not only restores the luster to the kitchen, but also helps renew its surface and make it more resistant to damage. Sanding kitchen marble is the ideal solution to restore its shine. Roofs.

Start first with coarse sandpaper, about 120-200 grit, to remove deep scratches, then move to fine grit sandpaper, 400-800 grit, to smooth the surface and get rid of small scratches. By using you With these types of sandpaper you can get excellent results in renovating your kitchen.

You can contact Blask Company, the exclusive and sole agent for PODIM & Pegas & Paco, to find out the price of 120 meters of sandpaper and 3000 sandpaper through phone numbers or through our website.

Read more: marble sandpaper